ASTM, AMS, & Mil-Spec Plating in Erie, PA

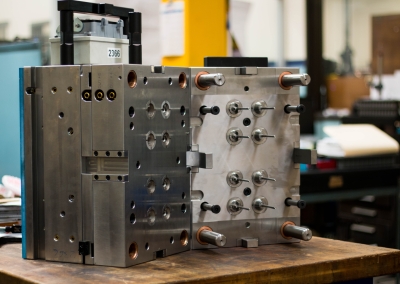

At Micro Plating Inc., our team specializes in uniform applications of high- and medium-phosphorus electroless nickel plating, black electroless nickel plating, proprietary MicroLube (PTFE), and MicroSlik (Boron Nitride) plating solutions to complete ASTM B733, AMS-C-26074, and Mil-C-26074 plating work, and more. Our Erie, PA-based electroless nickel plating facility also offers value-added services like glass bead blasting and baking in an inert atmosphere to ensure our electroless plating work is as beneficial as possible at competitive prices and expedited turnaround times.

Comprehensive Electroless Plating Services

High-Phosphorus Electroless Nickel Up to 0.0035

AMS 2404, ASTM B733, MIL-C-26074 Technical Specs

MicroLube (PTFE) & MicroSlik (Boron Nitride) Plating

MicroNite Black Electroless Nickel Plating

Low-phosphorus concentration black electroless nickel plating, MicroNite, delivers the same beneficial properties as standard electroless nickel plating but with a black conductive exterior that is aesthetically pleasing and useful for specialty applications. With excellent corrosion resistance, wear resistance, and a uniform coating over unique part geometries, black electroless nickel is quickly becoming a highly sought-after plating solution for medical, petrochemical, power generation, aerospace, and defense industries. MicroNite black electroless nickel plating is ideal for non-reflective applications like optical products, defense applications, and telecommunication components.

Glass Bead Blasting & Baking