MicroSlik Proprietary Boron Nitride Coating from Micro Plating Inc.

MicroSlik meets specs including AMS-2404, AMS-2454, ASTM B733, Mil-C-26074, and more while also being an RoHS and REACH compliant coating.

WHAT IS MICROSLIK BORON NITRIDE COATING?

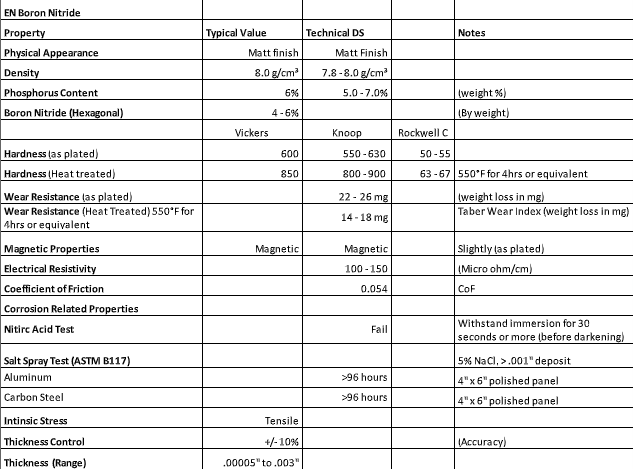

MicroSlik is an electroless nickel deposit that includes a homogenous dispersion of Hexagonal Boron Nitride particles. The use of these particles in the plated coating is what gives our proprietary coating its unique qualities. MicroSlik is formulated with a base of medium phosphorus electroless nickel that incorporates a uniform distribution of Boron Nitride particles throughout the coating's thickness. This results in fresh particles of Boron Nitride being exposed as surface wear occurs. This self-renewing feature results in a consistent performance of the plated coating.

WHAT FRICTION COEFFICIENT AND LUBRICITY DOES MICROSLIK OFFER?

Our proprietary MicroSlik Boron Nitride coating in the as-plated condition is similar in hardness and lubricity to Electroless Nickel/PTFE composite coatings. For high wear applications, MicroSlik Boron Nitride coating can be heat treated to a more effective temperature as compared to PTFE. This results in a harder coating which provides superior abrasion and wear resistance while remaining slick. Boron Nitride's natural lubricity, along with thermal and chemical resistance, provides unique properties when combined with the well known properties of electroless nickel. When combined, they result in a dynamic coating that offers moderate corrosion protection, excellent lubricity and wear characteristics in one coating.

HOW HARD IS MICROSLIK AND WHAT CAN IT COAT?

As-plated MicroSlik has a hardness of 48-52Rc, and when heat treated it can achieve 62Rc. Given its default hardness range, some customers find it unnecessary to heat treat their parts to receive adequate protection. When it comes to metals that MicroSlik can coat, with the proper pretreatment, most common metals can be plated with this Boron Nitride coating. Some examples of metals Micro Plating is currently capable of coating include aluminum alloys, copper alloys, and steel alloys (including 300 and 400 series stainless steels).

WHEN IS MICROSLIK AN IDEAL COATING CHOICE?

MicroSlik is an ideal coating option when your application would benefit from the lubricity of an EN/PTFE deposit but demands greater wear resistance. In these situations, MicroSlik's low coefficient of friction combined with its wear resistance offers the perfect solution. Whether you are in the process of manufacturing a product that needs to be coated or you are seeking to enhance the performance of an existing one, MicroSlik Boron Boron coating can meet your requirements.

COMMON MICROSLIK USES

- Pharmaceutical tablet punches

- Medical equipment

- Stamping tools

- Automotive applications

- Packaging equipment

- Adhesive machines

- Spray nozzles

- Any application that involves friction or sticky substances.

ADVANTAGES OF MICROSLIK

- Dry lubricity works up to 1600ºF. Much higher than PTFE which is 550ºF

- Excellent wear resistance

- Corrosion resistance

- High hardness, (as-plated hardness of 48-52 Rc can be heat treated to achieve 62Rc.)

- 100% coverage with uniform thickness

- Uniform coverage can be polished to a high luster

- Allows use of easily machined or cheaper base materials.

- Sightly magnetic coating

- Perfect antidote to sliding wear with high hardness

- Provides low coefficient of friction

CONTACT US

Footer form

We will get back to you as soon as possible.

Please try again later.

Location

8110 Hawthorne Dr.Erie, Pa 16509

Contact Us

Micro Plating Inc. | All Rights Reserved |

Created by Olive + Ash.

Managed by Olive Street Design.